Products & Applications

Products

-

Heat Transfer

Heat Transfer -

Headers & Connections

Headers & Connections -

Inner Distributing Tube Steam Coils

Inner Distributing Tube Steam Coils -

Outer Frame & Transition Assemblies

Outer Frame & Transition Assemblies

HEAT TRANSFER

Finning Methods:

Finning Methods:

- Edge Wound

- Footed “L” Fin

- Embedded

- Extruded

- Welded Fin

Tubing Materials:

- Aluminum

- Copper

- Copper Nickel

- Carbon Steel

- Stainless Steel

- Hastelloy®

- Inconel®

- Duplex stainless

- other materials also available to fit specialized applications.

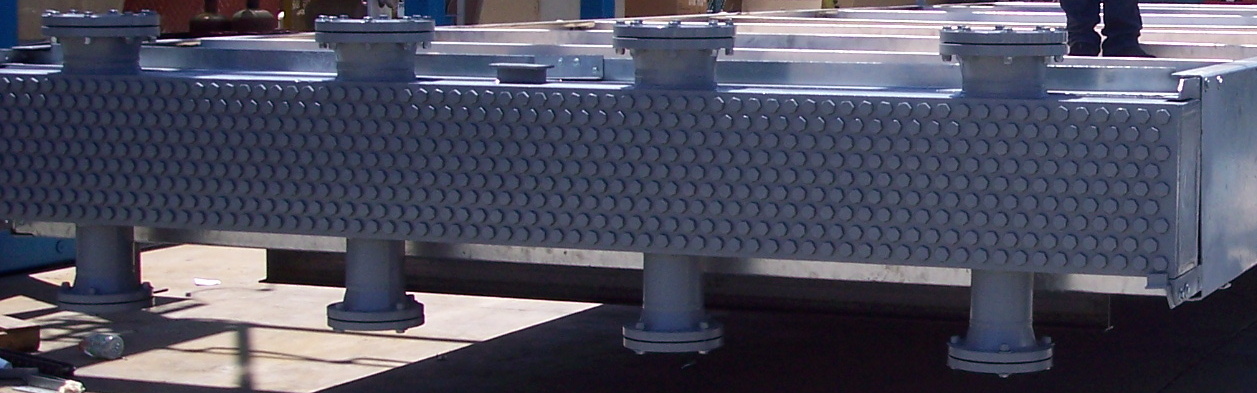

HEADERS & CONNECTIONS

Available in a wide variety of configurations, including fabricated boxes, rectangular tube or round pipe barrels. The connections can be supplied with a number of different mating styles, including:

Available in a wide variety of configurations, including fabricated boxes, rectangular tube or round pipe barrels. The connections can be supplied with a number of different mating styles, including:

- Raised Face Slip-On (RFSO)

- Rasied Face Weld Neck (RFWN)

- Raised Face Threaded (RFTHD)

- Male Pipe Thread (MPT)

- Victaulic Grooves

- Plain or Butt Weld Ends

Typical joining methods: brazing, rolling, welding, orbital welding.

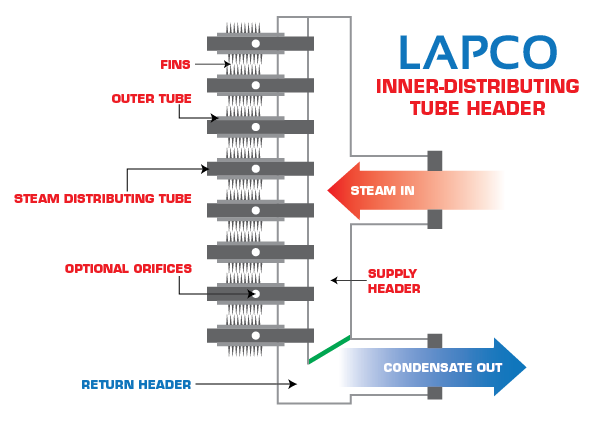

Inner Distributing Tube Steam Coils

Commonly referred to within the industry as “non-freeze” coils, this type of coil is typically specified for applications that may use 100% outside air that is 32°F or below. While certain conditions may still cause steam coils to freeze—particularly if they are not properly specified, designed, manufactured, and installed. LAPCO engineers are familiar with the special considerations associated with extreme environments.

Commonly referred to within the industry as “non-freeze” coils, this type of coil is typically specified for applications that may use 100% outside air that is 32°F or below. While certain conditions may still cause steam coils to freeze—particularly if they are not properly specified, designed, manufactured, and installed. LAPCO engineers are familiar with the special considerations associated with extreme environments.

Outer Frame & Transition Assemblies

Applications

Industries Served

You can rely on LAPCO to deliver cost-effective, reliable systems design and integration for a full spectrum of applications, including:

- Combustion Air Reheating

- Boiler Air Preheating

- De-superheating

- Pocket Vent Heating

- Fluid Bed Heating

- In-Bed Drying

- Economizers

- Wall Heaters

- Flue Gas Reheating

- Biomass Heating and Cooling

- Oil Coolers

- Turbine Inlet Heating & Cooling

- Sub-Cooling

- Generator Cooling

- Autoclave

- Air-Cooled Condensers